Ceramics in Space

CERAMICS IN SPACE

The inherent brittleness of ceramics is the main

reason why they are unsuitable as structural material for most applications.

However, ceramics do stand out in many highly specific aspects, especially when

it comes to high temperatures and chemical stability. In this article, we

explore the crucial roles of ceramics in spacecraft and how they save the day

where metals falter.

Thermal protection system in spacecrafts:

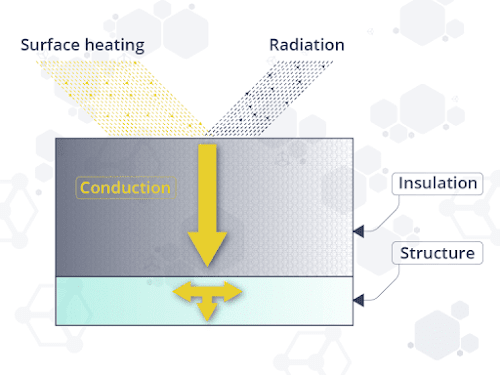

One of the more common use cases for ceramics in spacecraft is as part of

the thermal protection system. To understand why a ceramic material is the

ideal candidate for this application, it is important to look closely at the

different heat dissipation mechanisms.

When a spacecraft enters

any kind of atmosphere at orbital speeds, it experiences significant surface

heating through atmospheric drag. This holds even true for the relatively thin

Martian atmosphere, which has only 1% of Earth’s atmospheric density. The heat

absorbed by the spacecraft can then take two ways: it can be radiated into the

environment or conducted into the interior of the spacecraft, as indicated in

the figure 1.

Radiation would be a

favourable way for the spacecraft designer to get rid of the absorbed heat,

since the environment is hardly affected by the radiated heat, while the

spacecraft could disintegrate and/or melt if too much heat is accumulated

during the entry phase.

However, the efficiency of radiation is tied to the fourth power of the surface temperature. This means that it plays hardly any role for surface temperatures most materials can comfortably handle but becomes the dominant heat transfer/cooling mechanism at temperatures above ~1000 K. You may be familiar with this temperature range as virtually all solid materials start to visibly glow red around here .

Specialized coatings

are the key :

The conduction of the heat into the

spacecraft is the less favourable way to handle the surface heating because of

the temperature limitations of all used materials within the spacecraft. There

is only so much heat the spacecraft can absorb before the material limits are

exceeded and catastrophic failures may occur.

Engineers came up with a smart solution that utilises both heat transfer mechanisms. For example, the heated surface of the space shuttle orbiter is covered with a good heat-insulating material, namely silica (silicon dioxide). In addition, a black borosilicate coating is applied to this material in order to maximise the radiation emission properties of the surface. This way, up to 95% of the encountered heat is shed away immediately, leaving only 5% of the heat to be absorbed by the interior of the tiles.

The entire lower surface of the

space shuttle orbiters is covered with these black tiles, consisting out of a

silica fibre system with a volume content of only 6%. The remaining volume is

filled with air. Each tile is marked with an identification number to ensure

the correct maintenance and assembly in its unique position. The tiles are

bonded to the underlying aluminium structure with a silicon rubber “glue”.

Other thermal protection systems,

such as abrasive systems, also use insulating materials, which are deliberately

being eroded by the excessive heat. By design, the abrasive systems can only be

used once before they require a complete replacement. In contrast, the silica

tiles are reusable, despite their impressive peak service temperature of about

1900 K during the reentry phase.

SPACE SHUTTLE TILES

For

especially strongly heated areas, like leading edges of aerodynamic structures,

thermal insulation can be insufficient, requiring active cooling. In this case,

there is no insulating ceramics layer but a relatively thin, thermally

conductive material in place.

The

atmospheric entry phase is not the only operational phase where a spacecraft is

subjected to considerable surface heating. Simply being exposed to the sunlight

in space can raise the surface temperature quickly up to about 500 K.

Against

this, the space shuttle orbiters were protected by the same silica tiles using

a white coating, consisting of a mixture of silica compounds and aluminium

oxide, to maximize the surface reflectivity and absorb only a miniscule

fraction of the incident solar energy flux.

Spacecraft windows :

Glass-ceramics

are a little more familiar to most of us, if by another name: Gorilla Glass,

which is commonly seen in smartphones today. It’s an Aluminosilicate glass

formed by letting molten glass nucleate around ceramic dopant particles that

are only soluble at high temperatures. When it cools, this gets you somewhere

between 50 and 99% crystallinity, according to Corning. The resultant material

is very little like a glass except for its transparency. When tempered, the

balance between tension and compression makes the stuff tough as hell.

Glass-ceramics also play well with electrically conductive coatings, and

engineers use that feature on spacecraft windows to keep them free of

condensation and ice.

Carbon fiber showing off its flexibility and

luster. Carbon fiber wraps lend enormous tensile strength to applications like

aircraft fairings and spacecraft landing legs, while contributing little total

mass.

Spacecraft windows are a great application of

materials science. One way of making space-worthy windows is fused silica,

which is 100% pure fused silicon dioxide. Another crazy window material is aluminum

oxynitride, which is actually a transparent ceramic we use to make things

bulletproof. In a video produced by one manufacturer of aluminum oxynitride

bulletproofing products , 1.6 inches of AlON was sufficient to completely stop

an armor-piercing .50 cal round. AlON and fused silica both start out as a fine

powder called frit, which is tamped into a mold and then just baked at the most

unearthly temperatures into a single piece of transparent, super-hard material.

Next-Gen Spaceships using 3D - Printed Ceramics :

Engineers have always

liked ceramic parts – they are strong, lightweight and handle heat better than

many metals, ideal for crafting parts for airplanes or rockets. Heat-shielding

tiles on the space shuttle were made from ceramics, for example.

Now researchers have used a 3D printer to make customized ceramic parts

that have also overcome the Achilles’ heel of ceramic objects: their tendency

to crack.

"If you go very fast, about 10 times speed of sound within the

atmosphere, then any vehicle will heat up tremendously because of air

friction," said Tobias Schaedler, senior scientist at HRL Laboratories in

Malibu, Calif. "People want to build hypersonic vehicles and you need

ceramics for the whole shell of the vehicle."

Schaedler and colleagues at HRL invented a resin formulation that can be

3-D printed into parts of virtually any shape and size.

The printed resin can then be fired, converting it into a high strength,

fully dense ceramic. The resulting material can withstand ultrahigh

temperatures in excess of 1,700 degrees Celsius (3,092 Fahrenheit) and is 10

times stronger than similar materials.

Ceramics are much more difficult to work with than plastics or metals

because they cannot be cast or machined easily, according to Schaedler, who is

an author on the new study appearing today in the journal Science.

But Schaedler's team figured out how to trick ceramics into behaving like

plastic."We have a pre-ceramic resin that you can print like a polymer,

then you fire the polymer and it converts to a ceramic," he said.

"There is some shrinkage involved, but it's very uniform so you can

predict it."

The big picture is that this method could help rocket and satellite

designers who have to make lots of special small parts that are capable of

resisting the heating that occurs during high velocity air friction, as well as

high temperatures generated by the exhaust during takeoff.

Silicon Nitride Ceramics possesses ideal Properties :

The

electrical conductivity of materials used for the specimen holders must not

interfere with the coil’s electromagnetic fields. Moreover, the specimen

holders must exhibit extreme resistance to heat. The advanced silicon nitride

ceramics used here offer all of the material properties required to meet these

specifications.

Comments

Post a Comment